Blog

Scott Bennett - January 18, 2010

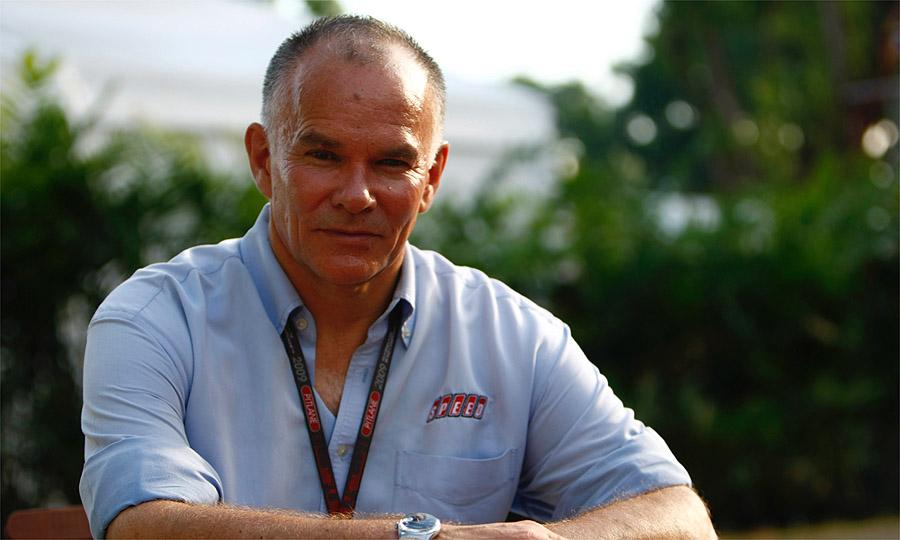

Scott Bennett is one of US F1 Team's senior designers. A graduate of Automotive Engineering from Loughborough University in London, Bennett has worked in auto racing notably with Falcon Cars and G Force, as well as the aviation industry. A native of Denver, Colorado, Bennett also designs a line of furniture which can be seen at housefish.com.

Almost nobody knows it, but this team has come an unbelievably long way since it was first announced on Speed TV 11 months ago. I was at that press conference, and I was one of the first three or four people to start working on the design of the car shortly afterwards, all of us crowded with our computers around a wobbly conference table in a dreary, poorly configured former Nascar shop. I wish I had taken pictures.

A strange quirk of my career is that every vehicle I have ever been involved in designing (including a few Indycars, an off-road trophy truck, and a composite aircraft) have all been clean sheet of paper designs. I don't know what it's like to start with something that already exists and try to refine it.

When we started this car, we started with nothing but fundamentals. The majority of a modern F1 car is tightly defined by the rules, so there isn't scope these days to come out with a Lotus 88 or Tyrrell P34. But there is still a daunting set of basic parameters that you have to define before you can even start designing anything - things like wheelbase, drivetrain configuration, suspension layout, weight distribution. And when you're doing it for the first time, you don't have an in-built knowledge of what's worked in the past. Throw in some major rules changes in each of the last two off-seasons, and there are even more unknowns. On the other hand, knowing that you're facing a lot of unknowns also means you don't think you already know everything. Hubris has dashed far more dreams than humility.

I'm extremely fortunate in that I've been able to do most of the car's layout from day one - I've seen and had a hand in almost every step of its evolution. Primarily I've been responsible for the front and rear suspension, particularly packaging. This has been a huge challenge. F1 cars are small, and we are fitting a lot of stuff into a very tight volume. And we're doing a few things quite differently than they have been done in recent years. I can't give specifics (yet), but we've looked at everything with a fresh perspective, and come up with some different answers. We'll know whether they were the right or wrong answers soon enough, but our car certainly won't be a clone of anything else out there. And did you know that we're the only one of the four new teams designing our own gearbox...?

It sounds like a cliché, but I'm quite literally living the dream here, or at least my dream. For almost as far back as I can remember, I would wake up at 6:00am every other Sunday and watch the F1 race with my dad. He was a huge Lotus fan, so of course I was too. When I was nine years old I watched Nigel Mansell collapse pushing his car across the finish line in Dallas. A year later I watched Senna win his first race, a brilliant drive in the rain at Estoril. I would read all the F1 technical books I could get my hands on, examine die cast F1 cars for hours, and try to draw my own. Where my friends wanted to be astronauts or firemen, I wanted to be Colin Chapman.

I ended up going to Loughborough University in England, to get an Automotive Engineering degree, because I figured that would bring me closer to a spot in F1. During my summers home, I got a data acquisition engineering job with Bradley Motorsports, an Indy Lights team based in my hometown of Denver. But things don't always work out the way we plan, and by the time I was finishing my degree I had collected a nice stack of rejection letters from every existing F1 team (and Lotus Cars, of course).

I came to US F1 through a long association with Ken Anderson. We first worked together at Bradley almost exactly 15 years ago. As things worked out, he got the job to design the original G-Force IRL car just as I was finishing up at school, still wondering what the hell I would do with my life. The day after my last exam at Loughborough, I drove down to Sussex and started working on that car, which won its first race, then the Indy 500, and the IRL championship. Ken and I have worked together off and on ever since.

I had given up on ever getting into Formula 1 around a decade ago. By the time I was 25, I had a good degree from a UK university, I had been involved at a high level on the design of a couple of successful top level racing cars, I had designed racing shock absorbers, and I had written suspension geometry and vehicle simulation software. I still couldn't get so much as an interview with a team. I don't hold a grudge about it. I always felt it was more puzzling than anything else.

Almost as long as I have known him, Ken had talked about his plan to someday build an American F1 team, but I never put much stock in it. It seemed such an utterly impossible task. Until a couple of years ago, anyway, when he somehow managed to finally put all the pieces together. And now here we are, only a handful of weeks away from having our car run its first race. In less than a year we've built a very capable shop, put together the smartest and most talented group of people I've ever had the privilege of working with, and designed what should be a fast, reliable, safe, drivable, and yes, beautiful car.

This team means a lot of different things to a lot of different people, but for me it's literally a dream come true. When those lights go out at the start of our first race, it will be both the end of a long road, and the start of a new one. I can't wait.

Peter Windsor - January 1, 2010 - Charlotte

It's great to be back in the USA! We're all complaining a little about everything closing down for the New Year but – believe me – America is currently much more industrious than the UK. Here, at our home base, we were quiet on Christmas Day (naturally) and then again today. The UK – and most of Europe – basically shut down on December 18 and will not stagger back to life until January 4. That's 16 valuable days lost in the too-short life of the F1 European winter.

And that's not all: remember the August F1 shut-down that was introduced for the first time in 2009? Well, it's happening again in 2010. Understand that most of Europe closes for August and you kind of understand the decision. Unless you're American, that is. As in Australia, August for Americans is just another working month in which some people maybe take a week or two away. There's no nationwide shut-down, as such – not of the type that regularly afflicts massive F1 teams like Ferrari. For years all of their suppliers have been shutting their doors for the month of August – and for years the European teams have been complaining that the situation has been growing worse, not better.

There was an F1 team meeting vote in the early fall about whether the 2009 F1 August shut-down had been a "success". I was impressed to hear the McLaren guys say that it was a waste of time and that most of their staff had found it all very frustrating, but sadly these were lone voices: the majority of the teams, led by Red Bull, it seemed to me, are firmly committed to the summer shut-down. And so shut down we will.

For now, though, it's winter in Charlotte; no doubt about that. It's a nice winter, though: the skies are invariably blue come lunch time and out the back of our factory, in the loading bays, we've already had the first of our team barbecues. Try doing that in the middle of the European winter!

I consistently make the comparison between here and there because our American base is the essence of US F1. I count on one hand the F1 people who, when we spoke about it, immediately grasped the logic of locating our team in North Carolina – and so you don't need me to tell you that "popular" F1 opinion was that it couldn't be done. Aside from the ease of setting up a facility like ours – the US F1 factory was an empty shell 14 weeks ago, remember – there is the support system around us. And the lack of congestion. And, for a company operating on the global stage via a European regulatory hub, the order and method of the US working day. You start as Europe is entering its afternoon frenzy, fresh and ready. You match that until lunch time – and then in the afternoon you move forwards, untroubled by interruptions from the F1 world outside. I remember my factory days at Williams as endless series of meetings and fragmented discussions; there were never the productive five or six hours we now have in the American afternoon.

So it's great to be back. The place is full of energy, full of expectation. No-one is taking anything for granted; everyone is working as hard as the human system will allow.

And the first chassis – top, bottom and nose – sits upon the Bay Cast flat plate in the R&D shop; it looks gorgeous. Soon we will be fitting all the electrical components, spring/damper units and suspension arms; the front and rear wing main planes are nearly finished and over in California Kenny Hill and Gordon Kimble are not too far away from completing the first batches of axles, hubs and bearing clusters. The car grows, in other words, with every passing day. It draws you like a magnet, away from your desk, just for a few moments, again to see its line. Then you quickly walk over to the boys in the composite department, where they're laying-up another mold, or to the machine shop, where the guys are programming another front upright. Then the phone rings and you're back in your office, talking on speakerphone, watching out the window as yet another group of visitors pulls up and walks towards Reception. Some are fans, flying in on spec from places like Florida or Wisconsin; most are suppliers or contacts, keen to help and only too happy to play a role.

I hope you like this website. As I've said before, it's for you, the F1 fan. Let us know what you think. Give us your input and your ideas. The stats – the website, Facebook, Twitter and video hits – tell us that you love it; remember, though, that this is just the start. We haven't yet raced; we haven't yet finished our first car. Huge growth is ahead of us – and that includes this site, too.

Thanks to everyone who so kindly sent gifts and cards over Christmas. I love the Paul Newman book; the Jim Clark driving gloves are a perfect fit; and I think Spencer Owyang's Christmas tree bauble will be the envy of every Ducati owner in the country.

Best wishes to everyone for a happy and healthy 2010.

Peter Windsor - December 22, 2009

A lot has happened since we announced our plans for the US F1 Team back in February 2009, and I’m sure that most of you will be aware of the broad picture - the economic world recession and political issues in F1 born indirectly of that downturn effectively cut seven months from our year. One minute we were planning the team in detail, the next we were wondering if we’d have a single F1 World Championship.

It wasn’t until late July, therefore, that we were finally invited to sign the Concorde Agreement and officially become a team in the FIA Formula One World Championship. I think the pen Ken used to sign the Agreement has been set aside for some money-raising (for charity!) but, beyond that, there was very little time to celebrate and take stock. With the fall looming, we had a race car to build and a team to form.

For my part, the second half of 2009 passed in an emotional whirl. I’ve been incredibly lucky to have worked in F1 now for 35 years and for the past ten of those years I worked primarily for SPEED TV in the US and F1 Racing magazine in England. Add some opportunities to work for FOM TV with the post-qualifying and post–race interviews and to speak at events for Grand Prix Tours and major F1 sponsors and you could say that I pretty much had the perfect life. I worked for myself. I attended all the F1 races and I could enjoy the benefits of ultra-professional back-up from the SPEED crew back in Charlotte.

It was when people began to come up to me and say things like, “Boy, you’re brave!” or “Why are you giving it up?” that I guess I began to feel a little nostalgic. By the time I got to Abu Dhabi I felt positively teary-eyed at the thought of my little era coming to an end. I remember chatting to Jonathan Nicholas, one of the very talented producers at FOM TV, on the Thursday of Abu and saying something like, “Hey, I’m going to miss you guys,” and being very surprised by his response: “Yeah, but what you’re going to be doing is fantastic. You can’t even begin to imagine how much fun you’re going to have. It’s brilliant. And you can still do all the TV and writing you want.”

Thanks, Jon, for that. If there was a turning-point in my recent life it was that moment as the sun was setting on the Gulf.

Since then, I say without hesitation, I’ve never looked back. I’ve been wondering for a while how I can express in words the feeling of watching an F1 team growing around you, of wonderfully talented people beginning to mix and to produce gorgeous mechanical parts with increasing frequency. To me, this is as good as it gets in an F1 sense. Yes, it was fun hanging out with the drivers when I was a journalist at Autocar, or talking to Fernando on the grid for SPEED, or trying to get Kimi to smile in the post-race interviews, or flying to Warsaw with DC for F1 Racing - yes, these were all highlights.

For me, though, there is a new thrill in my F1 life. It is walking into the break room in our headquarters in Charlotte and finding one of our talented designers or engineers stirring a coffee and being able to say something like, “How’s it going? What are you working on at the moment?”

Of course, I could always ask engineers questions like that in my former life. It’s just then I knew I wouldn’t receive a meaningful answer – not unless it was Colin Chapman (who was always open and honest) and perhaps Gordon Murray.

Now, though, there is no doubt. I’m in the heart of it. And I love it.

A number of people have asked me why we’ve been relatively quiet over the past six months or so. My answer is twofold - one, while the F1 politics were sorting themselves out there was very little that we could do or say. We’re all in the entertainment business we call F1 and there seemed little or no point in adding to the situation from the perspective of a new team.

Second, since August, we have been building our “house”. Literally. We gutted the ex-Hall of Fame Racing/Joe Gibbs NASCAR shop, re-painted it, re-floored it, re-wired it, re-lit it and re-designed it. In three weeks. That’s what you can do in Charlotte, North Carolina, where the economic impact of the motorsports industry approaches $6 billion per year. Ask and you will receive. Brilliant.

And then, once we had a building (and even before we had one), we began to design parts and to hire our team. Again we were building. People wanted to know what was “going on.” We replied that we were “putting together the team.” It’s a bit like building a new house. You don’t invite all your neighbors and family around to see it at least until you’ve got the living room almost done, or a few plates in the kitchen.

Such are the demands of modern media, however, that every passing minute is another step into history - if you’re not saying something, you’re not doing anything. Well, I disagree. I think everyone and every company is entitled to its heads-down time. It reminds me of the time a young Winston Churchill left the clamor of London to travel by ship to cover the Boer War in South Africa for an English newspaper. During the voyage he enjoyed two weeks of seclusion from any news about the war he was about to write about. And guess what? The war was still raging when he arrived, he quickly brought himself up to speed – and his mind was so fresh that he was able to compose some of the best pieces of war journalism in the history of the English language.

Now, though, the New Year is upon us. US F1 Team will be racing in 2010 and so it is now precisely the time to share with you our life on the global stage. So let me take you on a quick tour. In the drawing office, which is one large room filled with CAD stations looking directly onto the race bays, we have American designers and engineers and also engineers from some of the major F1 teams – Brawn, Renault and Red Bull to name but three. In our creative department (TV, animation and layouts) we have editors and designers from SPEED, Weta Digital (Peter Jackson’s company for all of you movie fans out there) and other Hollywood studios. In our machine shop we have a floor-full of 3- and 5-axis routers and CNC machinery from Haas Automation and C.R. Onsrud. Our chief fabricator worked for Ken at Onyx F1 and for me at GTO. In the composite shop, we have technicians from aerospace and motorsports (including F1). The sub-assembly area, overlooking the prototype build room, is headed by a man who worked for Ken in American open-wheel racing.

And that’s not all….

Unlike many of the other F1 teams, we have not been burdened from the start by having to build a wind tunnel, or a large CFD department, or a shock absorber department complete with its own testing rigs, or a space- and dollar-consuming seven-post shaker rig or even a lot of free space for trucks and motorhomes. We decided to base our F1 team in Charlotte because it is the epicenter of racing in the United States. This coupled with the fact that most of the technology currently in F1 is a product of the American aerospace industry makes Charlotte the perfect choice. Around the corner we have Crawford Composites, where they produce excellent work under the ever-detailed management of Mr. and Mrs. Max Crawford. Gunther Steiner, the very talented and under-rated former Technical Director of the Jaguar F1 and the Red Bull NASCAR teams, has a similar, five-star composite facility a few miles up the I-77.

RaceWorks, ten minutes away, has a 2010-spec seven-post shaker and some great guys there, including some ex-Williams boys. Then there’s Corvid, the CFD company co-founded by Dr. Eric Warren, who works now as our Chief Aerodynamicist. Understand that Corvid’s core work is for the U.S. Defense Department, and that the bread-and-butter of the company is to design coding for something as serious as a bomb explosion (that’s right - they map the path and movement of bomb fragments and debris in the milliseconds after explosion) and you will understand that the Corvid folks are enjoying the challenges of F1 turbulence and double-diffusers the same way you and I would enjoy, say, a decent filet steak. What does the Defense Department think? Well, being racers, the boys at Corvid always kept 20 percent of their capacity free for “other projects.” Like JRi Development Group, who are designing and building our shock absorbers, Corvid is based just up the road in Mooresville – up there with McLaren Electronics Systems, USA.

I noticed the other day that Nick Wirth issued a press release about the new Virgin F1 car being entirely designed on CFD – Computational Fluid Dynamics (rather than in the wind tunnel). The same thing applies to our car, although we see this as a logical process for a new team rather than something about which to be particularly excited. There’s no doubt, though, that the rhythm of life is now different, having worked for both Williams and Ferrari I have no hesitation in saying that.

Back then, each sixty percent scale-model iteration followed another. In the background, old Basil ground away on the chassis “buck”, grumbling about last-minute changes he didn’t need and aerodynamicists who did too much “fiddling.”

Today, the designers design away on CFD, 3D’ing and calculating, 3D’ing and calculating. The design process is more accurate, more complete and, from the outside (I assume, given some of the comments made from afar) apparently more time-consuming. And then – as if by magic – the drawing is released and a robot orchestrated by our machine-shop guys creates that part from (typically) an aluminum block (if it’s a bulkhead, for example) or a synthetic wood (if it’s a pattern for a carbon mold). With us, in other words, it’s wait….wait….wait….and then very fast manufacture. Back then – and to some extent still today for the teams that are still modeling – it was wait…test….wait….test…build….test….wait…..go!

The Windshear Wind Tunnel, of course, was our “stake in the ground”. Gene Haas (of Haas machine tool fame and not to be confused with Carl Haas, who owns Newman-Haas Racing) believed Ken Anderson when Ken told him in 2006 that it would be relatively straightforward to design and build a 180mph, full-scale rolling-road wind tunnel in Charlotte…and so it has proved. Windshear is about 15 minutes’ drive from our headquarters and will prove to be invaluable when we start to aero-map the full-size car in January. We have no model shop, in other words – and none of the expenditure and complication of running a model shop. Our “model” is the real car – and, as a new team in F1, we will be able to test at Windshear on numerous occasions in 2010.

A highlight of my early winter came in Spain, where Ken and I officially signed our agreement with the government of Aragon for our European headquarters. If I tell you that the new MotorLand complex in Alcaniz (reachable by high-speed train from both Barcelona and Madrid) boasts a beautiful new F1 circuit, a moto-cross layout, a world championship kart track, rally Tarmac and dirt stages, a medieval mountain town, gorgeous restaurants, sunsets, rolling hills and virtually no rain in winter (when F1 testing is allowed) I think you will understand, like us, that this is the future. With circuits like Monza, Barcelona and Valencia facing increasing pressure from environmentalists (a farmer near the Barcelona circuit recently won a large lawsuit because his cows stopped producing milk because of the noise of the cars and bikes!) the future is exactly as Bernie Ecclestone planned it - on circuits that can grow without limitation. At facilities like MotorLand Aragon. US F1 Team’s building there – overlooking the circuit – is nearly finished and in time I think will be a place for F1 fans to visit and just to have some fun. Shop in Madrid for a couple of days, take the high-speed train, see the facility, drive some laps, race a kart, meet the drivers, train it to Barcelona and then fly home to wherever. A perfect week for the family!

I write – would you believe – from the departure lounge of Orlando airport, where I await the (very) late departure of my flight to London Gatwick. I’ll be in England for a few days, visiting my family over Christmas and catching up with a few friends, but I’ll be back in Charlotte before the New Year. Very soon we’ll be announcing our driver line-up for 2010 plus a whole lot more besides.

I can’t wait.

- Peter